( Click image to enlarge )

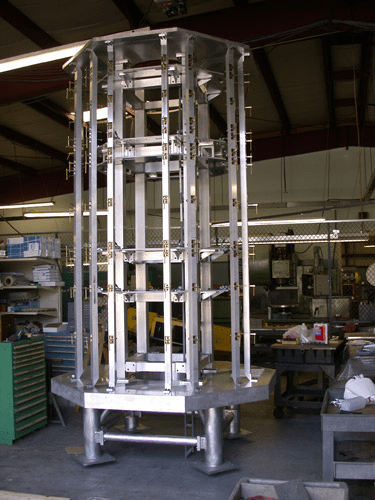

( Click image to enlarge )HYE Precision Products was contracted by an aerospace client to fabricate the composite bond assembly tool highlighted here. Our reputation as a provider of complex, precision equipment and assemblies played a key role in the awarding of this contract.

Composed of 6061-T6 aluminum, this tool was designed for use in the assembly of telescope barrels for spacecrafts. Design features included all aluminum construction, honeycomb sandwich base plates with edge close-outs, and tool controls for up to 32 hard tooling points. Components were fabricated using our advanced CNC milling capabilities, parts were then assembled with various welding and bonding techniques. The completed assembly featured dimensions of 80″ in length and width, 147″ in height, and weighing 1,450 lbs. This entire project was designed, fabricated, and delivered to the client’s facility in only 12 weeks.

To learn more about this project, or the processes used to fabricate it, see the table below or contact us directly.

Fabricated Aerospace Assembly Tool Project Highlights

- Product Description

- This is an Assembly Tool used for the Spacecraft Telescope Barrel

- Design Fabrication Capabilities Applied/Processes

- Primary:

Fabrication – CNC Milling, Welding, BondingSecondary:

Assembly

- Overall Part Dimensions

- 80.00″ Length x 80.00″ Width x 147.00″ Height Weight: 1450lbs

- Material Used

- 6061-T6 Aluminum

- Additional Facts

- Design Details:

- Aluminum Construction

- Honeycomb Sandwich Base Plate with Edge Close-Outs

- Tool Controls Thirty-Two Hard Tooling Points

- Industry for Use

- Aerospace

- Delivery/Turnaround Time

- 12 Weeks

- Standards Met

- Customer Specifications, 2D CAD Drawing

- Product Name

- Composite Bond Assembly Tool