( Click image to enlarge )

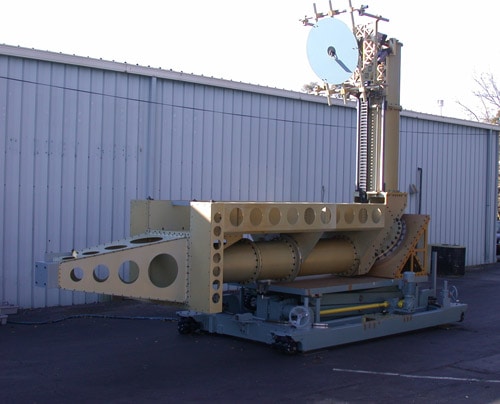

( Click image to enlarge )An aerospace client recently contracted HYE Precision Products for the design, engineering, and fabrication of an alignment fixture used to test satellite RF components. This large mechanical ground support equipment (MGSE) fixture, exemplifies our ability to create complex, robust systems for critical roles.

This unit featured a hexapon positioner with 6 degrees of freedom. It included a multi-axis servo with coordinated movement requiring custom Kinimatic Sofware. HYE Precision is one of only several manufactures in existence that can provide this type of system. Operated via touch screen HMI, and Ethernet communications, it is controlled by a PLC system and VFDs; it offers the operator several moving axis, which allow for multiple configurations. As well as being fully portable, the unit is capable of 130″ of vertical travel and includes an integrated, fully electric scissor lift.

Constructed from a combination of carbon steel and aluminum, we utilized our precision CNC milling and turning capabilities, as well as press brake forming and welding. The final dimensions of the fixture were 215″ in length, 100″ in width, 220″ in height, weighing 22,000 lbs. To learn more about this alignment fixture, or additional details of the fabrication process, please see the table below or contact us today.

Alignment Fixture for Satellite RF Components Project Highlights

- Product Description

- This is a Positioning Fixture used to test Satellite RF components.

- Design, Engineering & Fabrication Capabilities Applied/Processes

- Primary:

Design Engineering

Stress Analysis

Electrical Engineering

Fabrication- CNC Milling, CNC Turning

- Press Brake Forming, Welding

Secondary:

Assembly

Painting

- Overall Part Dimensions

- 215.00″ Length x 100.00″ Width x 220.00″ Height Weight: 22,000 lbs.

- Material Used

- Aluminum, Steel

- Material Finish

- Chem-film, Paint

- Additional Facts

- Design Details:

- Electro-Mechanical

- PLC, Touch Screen HMI, VFD’s, Ethernet Comm

- Servo Controller, Multi-Axis Coordinated Movement

- Custom Designed 6DOF Servo Hexapod

- Custom Six Axis Kinimatic Software

- Several Moving Axis Allow Multiple Configurations

- Extends up to 130 Inches of Vertical Travel

- Portable

- Industry for Use

- Aerospace

- Delivery/Turnaround Time

- 12 Months

- Standards Met

- Customer Specifications, 2D CAD Drawing

Designed to customers specified command media

- Product Name

- Antenna Range Fixture Positioning/Alignment Fixture